0009-0006-5023-9628

0009-0006-5023-9628  cirelys.correa@gmail.com

cirelys.correa@gmail.comSusana Díaz Aguirre2

0000-0002-6338-7519

0000-0002-6338-7519  sdaguirre@gmail.com

sdaguirre@gmail.comRay Leonard Sánchez Ramírez1

0009-0008-9735-1224

0009-0008-9735-1224  rayleonadsanchezramirez61@gmail.com

rayleonadsanchezramirez61@gmail.com

Cooperativismo y Desarrollo, September-December 2024; 12(3), e785

Translated from the original in Spanish

Original article

Management of conch and oyster processing residues. Characterization and local development opportunity

Manejo de residuos del procesamiento del cobo y del ostión. Caracterización y oportunidad de desarrollo local

Gestão de resíduos de processamento de conchas e ostras. Caracterização e oportunidade de desenvolvimento local

Cirelys Correa Carmona1  0009-0006-5023-9628

0009-0006-5023-9628  cirelys.correa@gmail.com

cirelys.correa@gmail.com

Susana Díaz Aguirre2  0000-0002-6338-7519

0000-0002-6338-7519  sdaguirre@gmail.com

sdaguirre@gmail.com

Ray Leonard Sánchez Ramírez1  0009-0008-9735-1224

0009-0008-9735-1224  rayleonadsanchezramirez61@gmail.com

rayleonadsanchezramirez61@gmail.com

1 Industrial Fishing Company of La Coloma. Pinar del Río, Cuba.

2 University of Pinar del Río “Hermanos Saíz Montes de Oca”. Center for Studies on Environment and Natural Resources. Pinar del Río, Cuba.

Received: 3/10/2024

Accepted: 12/12/2024

ABSTRACT

In the Industrial Base Business Unit of the Industrial Fishing Company of La Coloma, Pinar del Río, the conch and oyster production process generates solid residues that accumulates in inappropriate places, which represents a source of contamination that threatens the health of workers and the environmental performance of the organization. The objective of this work is to characterize the management of solid residues generated in the conch and oyster production process, which will allow to valorize it and contribute to the development of the locality. A descriptive observational research was developed through the empirical methods of observation and measurement. The techniques used to collect information included documentary analysis, an observation guide, a survey of specialists and workers to identify the level of knowledge on environmental issues, and an interview with managers. The main results were that during the years 2022, 2023, and until April 2024, the company generated 455,466 tons of solid residues from the industrial process, of which 116,882 tons corresponded to oyster and conch shells that are not used. It was also found that there is insufficient training and awareness among workers on environmental issues and that the need to strengthen integrated management and proper handling of solid conch and oyster residues would minimize environmental impact and increase its added value, contributing to the development of the company and the locality.

Keywords: solid residues management; oyster; conch; residues utilization; local development.

RESUMEN

En la Unidad Empresarial de Base Industria, de La Empresa Pesquera Industrial de La Coloma, Pinar del Río, el proceso de producción del cobo y del ostión genera residuos sólidos que se acumulan en lugares inapropiados, lo que representa una fuente de contaminación que atenta contra la salud de los trabajadores y el desempeño ambiental de la organización. El trabajo tiene como objetivo caracterizar el manejo de los residuos sólidos generados en el proceso productivo del cobo y del ostión lo que permitirá valorizarlo y contribuir al desarrollo de la localidad. Se desarrolló una investigación observacional descriptiva a través de los métodos empíricos de observación y medición. Se utilizaron como técnicas de recogida de información el análisis documental, la guía de observación, la encuesta a especialistas y trabajadores dirigida a identificar el nivel de conocimiento sobre los temas ambientales y la entrevista a directivos. Como principales resultados se obtuvo que, durante los años 2022, 2023 y hasta abril del 2024, la empresa generó 455,466 toneladas de residuos sólidos provenientes del proceso industrial, de los cuales 116,882 toneladas correspondieron a las conchas del ostión y del cobo que no son aprovechados. Así como también se constató que es insuficiente la capacitación y sensibilización de los trabajadores sobre los temas ambientales y que la necesidad del fortalecimiento de una gestión integral y un adecuado manejo de los residuos sólidos del cobo y del ostión minimizarían el impacto ambiental, aumentarían su valor agregado, contribuyendo al desarrollo de la empresa y de la localidad.

Palabras clave: manejo de residuos sólidos; ostión; cobo; aprovechamiento de residuos; desarrollo local.

RESUMO

Na Unidade de Negócio Base Industrial da Empresa Pesquera Industrial de La Coloma, Pinar del Río, o processo de produção de búzios e ostras gera resíduos sólidos que se acumulam em locais inadequados, o que representa uma fonte de poluição que ameaça a saúde dos trabalhadores e o desempenho ambiental da organização. O objetivo deste trabalho é caracterizar o gerenciamento dos resíduos sólidos gerados no processo de produção de búzios e ostras, o que permitirá sua valorização e contribuirá para o desenvolvimento da localidade. Foi realizada uma pesquisa observacional descritiva usando métodos empíricos de observação e medição. A análise documental, um guia de observação, uma pesquisa com especialistas e trabalhadores com o objetivo de identificar o nível de conhecimento sobre questões ambientais e uma entrevista com gerentes foram usadas como técnicas de coleta de informações. Os principais resultados foram que, durante os anos de 2022, 2023 e até abril de 2024, a empresa gerou 455.466 toneladas de resíduos sólidos do processo industrial, das quais 116.882 toneladas corresponderam a conchas de ostras e búzios que não são utilizadas. Também foi constatado que o treinamento e a conscientização dos trabalhadores sobre questões ambientais são insuficientes e que a necessidade de fortalecer o gerenciamento integrado e o manuseio adequado dos resíduos sólidos de conchas e ostras minimizaria o impacto ambiental, aumentaria seu valor agregado e contribuiria para o desenvolvimento da empresa e da localidade.

Palavras-chave: gestão de resíduos sólidos; ostra; concha; utilização de resíduos; desenvolvimento local.

INTRODUCTION

The growing recognition of the importance of environmental protection and the potential impacts associated with manufactured and consumed products has increased interest in the development of tools to understand and reduce impacts on nature (Aranda Usón & Zabalza Bribián, 2010).

One of the main challenges faced by developed countries and emerging economies lies in the adoption of adequate solid residues management systems to facilitate the reception, classification and subsequent use of the different types of residues generated on a daily basis (Segura et al., 2020).

In the Caribbean countries, the policies needed to improve residues management require a quantum leap of effort and various strategies to reverse some of the environmental degradation and aesthetic deterioration that has been observed over the years.

The Economic Commission for Latin America and the Caribbean, in its 2021 report, states: The first thing that is needed in order to advance in the implementation of circular economy actions and/or productive linkages, which allow the development of existing activities and the flourishing of new sectors is to make a diagnosis of the situation and identify the potentials and challenges to transform residues management systems into resource management systems. The infrastructure necessary for the management, use and final disposal of residues is not growing at the same rate as its generation (de Miguel et al., 2021).

Solid residues management represents a growing global problem that directly affects different environments, including coastal and marine environments. The volumes and compositions of this residues are variable and depend on sociocultural aspects related to the lifestyles of societies (González Zevallos et al., 2020).

Fishing companies have begun to opt for the application of cleaner production technologies to reduce the polluting impact on the environment, while recovering valuable material that is incorporated into the main production process (Paredes Concepción, 2014).

Waste generated by the fishing industry has been gaining attention worldwide due to the growing demand for seafood products, its negative impacts on the environment and its implications for marine conservation and policy. This industry generates large volumes of residues, which includes processing residues such as shell, head, bones, intestine, fins and skin (Erasmus et al., 2021, cited by Florez Jalixto et al., 2021).

Every year, a considerable number of by-products derived from fish or shellfish processing are either disposed of or transformed into animal feed, fertilizers, or silage. These wastes can be converted into products tailored to the consumer, with high added value (Martínez Álvarez, 2011).

At present, Cuban companies are in a period of constant change, so it is necessary to be more concerned about how to adapt their processes and operations to: reduce the consumption of raw materials, reduce the generation of residues and try to recover most of it mainly through reuse and recycling processes, minimizing environmental impacts and ensuring cleaner production (Terry Berro, 2005), all of which will contribute to the sustainable development of the company and the locality.

In Cuba, awareness towards environmental protection in industries is a factor that has increased in recent years, which leads to the need to develop a set of actions aimed at ensuring the rational use of natural resources, prevention, reduction and control of pollution, care and preservation of the working environment, efforts to enhance recycling and raise environmental education so as to achieve an ecologically balanced, socially just and economically sustainable development, from outlining a policy (PNDES, 2019). In addition, a national environmental strategy that expresses the interrelation of the national environmental policy and other guiding documents of the country, which states and defines that, in response to the environmental problems that were identified, strategic directions and priority actions were established and that should be addressed territorially and sectorially, considering their link with the Natural Resources and Environment Macroprogram (Ministry of Science, Technology and the Environment -Citma-, 2021). Concern for environmental issues in all Cuban companies is a must and today constitutes a necessity in the search for the sustainable development of the economy.

In Cuba's National Environmental Strategy 2021-2025 (Citma, 2021), strategic axis number 3 refers to reducing and/or eliminating negative impacts on the environment and people's health through the development and reconversion of infrastructure, achieving sustainable management and efficient use of natural resources, promoting the adoption of clean technologies and industrial processes, as well as the management of municipal and other types of solid residues. Another of its priority actions is to prevent and confront the social indiscipline that affect environmental quality with the use of integral solutions and the participation of all sectors of society. This is where companies are linked to local communities through corporate social responsibility programs. This strategy highlights the role of companies to collaborate permanently in the care and protection of the environment, which contributes to their economic and social development together with the well-being of the entire community.

Law 150/2022 of the System of Natural Resources and the Environment in Cuba (National Assembly of People's Power, 2022), stipulates that pollution in the activities of the fishing sector must be reduced to a minimum, which includes the treatment of grease, oily water or hydrocarbons resulting from the bailing of vessels, remains of fishing gear and plastic residues. It also proposes minimizing the waste of catches of both target and non-target species, fish and others, and reducing the generation and aggressiveness of liquid and solid residues, hazardous waste and air emissions at the sources of origin.

The fishing industry is in a stage of development and significant increase in production levels, which necessarily requires an expansion of technological operations and the implementation of clean practices, measures and technologies. Faced with the problem of residues generation, innovative solutions must be provided to be more efficient in the management of resources, in the context of a circular economy, increasing efficiency and reducing consumption and pollution.

In other words, the continuous application of an integrated environmental prevention strategy for processes, products and services, in order to reduce risks to humans and the environment (Onudi, 2020), promoting environmental awareness to establish control and guarantee quality, establishing a residues policy that minimizes residues generation and favors residues management oriented towards circularity, promoting preparation for reuse and recycling, are less costly, simpler and continuous solutions to help companies reduce the environmental impacts of their activities.

The Industrial Fishing Company of La Coloma is located in the province of Pinar del Río, Cuba, and its corporate purpose is to capture, cultivate, industrialize and commercialize species from the platform, aquaculture, as well as those acquired from private commercial fishing. Capture, process and commercialize land crabs and provide maquila services to fishing products. Among its main processes are those of lobster, fish, sea cucumber, conch and oyster in which various production lines are involved.

At Industrial Fishing Company of La Coloma, the Base Business Unit (UEB) Industry, where the conch and oyster production process is carried out, it is generated solid residues that is a source of contamination due to the accumulation or dumping of this waste in inappropriate places, which causes non-compliance with applicable environmental legislation, threatens the health of workers and the environmental performance of the company, and the commercial value of the residues is not exploited.

The objective of this work is to characterize the management of the residues from the conch and oyster production process of the Industrial Fishing Company of La Coloma, which will allow to valorize it and contribute to the development of the locality.

MATERIALS AND METHODS

For the characterization of the management of solid residues generated in the conch and oyster production process at the Base Business Unit Industry of the Industrial Fishing Company La Coloma, the Methodology of the National Environmental Recognition (2020) - Criterion 2: Environmental Performance was used, which facilitated the tabulation for the characterization and analysis of the results. This methodology is an instrument designed by the Ministry of Science, Technology and the Environment to carry out environmental diagnoses that provide information on corporate environmental management.

The historical-logical method was used in the study, since it allows revealing the characteristics, regularities and tendencies in the process of study about reality.

A descriptive observational research was developed through the empirical methods of observation and measurement in which the behavior of the variables was analyzed in a determined period of time on the defined sample. Information was collected that demonstrated the relationships between the different variables and evidenced the characteristics of each one of them.

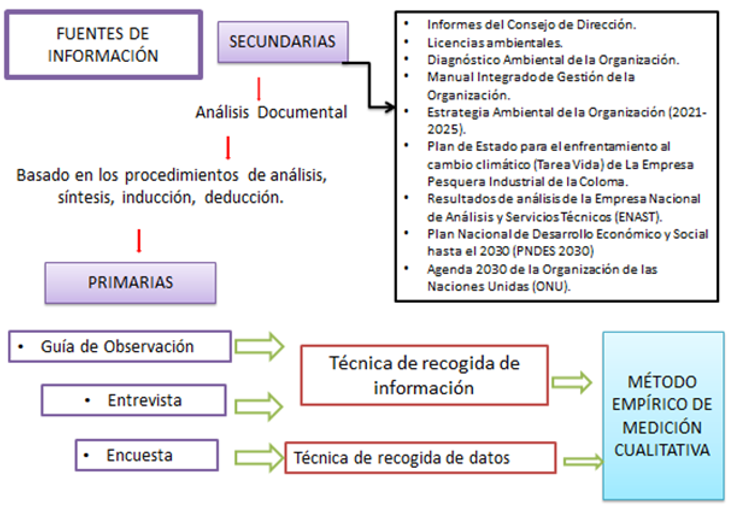

Different techniques were designed and applied, for which it was necessary to define the sources of information, empirical diagnostic methods to be used, procedures and techniques for the collection, storage and processing of information. The following is a description of the criteria to be followed in each one, according to the proposed objective:

Definition of the sources of information (secondary or primary).

For the review of secondary sources of information, documentary analysis was used, which allowed the analysis, synthesis, induction, deduction, for the collection of the necessary information on environmental issues. Documents of the organization as well as some of those governing environmental issues at the national and international levels were reviewed.

Several sources of primary information were used in the study, and taking into account the context and general characteristics of the organization, they were designed:

As empirical methods: The observation guide, interviews and surveys.

The observation guide as a method of empirical diagnosis allowed the direct, attentive, rational and planned perception of the environment in the UEB Industry, deepening the management of solid residues in the productive areas: Behavior of workers during production processes and outdoor areas, with more emphasis on those involved in the processes of obtaining the conch and oyster mass; if they knew the environmental impacts caused by the activity of the UEB Industry, the environmental situation of the productive areas, existence of contamination by solid and/or liquid residues.

The interview was designed and applied with the objective of enriching, completing or confirming the information obtained through the use of other methods. It was directed to managers, emphasizing which are the environmental problems and those that have more incidence in the UEB Industry, which activities caused these problems and the actions that are carried out to solve them.

The surveys were directed to specialists and workers with the objective of identifying the environmental problems considered to be present in the UEB under study and if they had any experience in the search for solutions to these problems.

Figure 1 below shows a summary of the sources of information described.

Figure 1. Sources of information used for the design of the tools to be used in

environmental diagnosis

Source: Prepared by the authors

In order to select the sample size, the purposive sampling technique was used, consisting of 7 managers, 11 specialists, 25 technicians and 107 workers. The latter were directed to those involved in the process of obtaining the conch mass (processors and sailors). Of the total sample, interviews were conducted with the 7 managers and the survey was applied to the rest of the workers of the UEB Industry.

The information collected was processed and analyzed to make decisions, using the Microsoft Office package for data processing in the case of surveys and documentary analysis.

RESULTS AND DISCUSSION

Industrial Fishing Company of La Coloma is located in the southern plain of Pinar del Río, practically at sea level and occupies an area of approximately 20 km2 south of the province of Pinar del Río. It belongs to the Fishing Industry Business Group of the Ministry of Food Industry. It is structured by 6 Functional Directorates and 7 Basic Business Units. The Industry UEB, which is where the research will be focused, is located in La Coloma, together with the Company Management, the Extractive UEB and the Guarantee UEB. It consists of two fish processing plants: the Lobster Plant and the Fish Plant (where industrial production is carried out both for export and for the domestic market). Its main products include: lobster, fish, shaped and sausage products, as well as the process for obtaining conch and oyster mass, which are the subject of characterization and solid residues management.

The analysis of secondary information sources, using the document review guide, corroborated how UEB Industry manages the environment, as well as the implementation of environmental activities. Compliance with environmental regulations was verified and it was found that the UEB has implemented a group of actions that contribute to the improvement of its environmental performance, but it has not yet included actions for the integral use of solid residues generated in the production of conch and oyster mass. The documentary analysis was carried out on the following documents:

The observation guide was used to evaluate the environmental surroundings of the UEB Industry. It was shown how the water and energy carriers behaved in the analyzed periods and the existence of solid residues contamination, mainly conch and oyster shell residues.

The UEB Industry generates various types of solid residues. Table 1 shows the classification according to origin and type of residues generated. In addition, the final destination of the residues is shown.

Table 1. Classification according to origin and type of residues generated in UEB Industry

Classification according to origin |

Type of residues generated |

Handling. Mark with an (X) |

||

Reuse |

Recycling |

Dump |

||

Domiciliary |

Food residues |

|

|

x |

Cardboard |

x |

x |

x |

|

Paper residues |

x |

x |

|

|

Equipment |

|

x |

|

|

Electronic equipment battery |

|

x |

|

|

Luminaires |

|

|

x |

|

Construction |

Wood |

X |

X |

X |

Metallic residues |

|

x |

|

|

Industrials |

Disused equipment |

|

x |

|

Wood |

X |

X |

|

|

Sawdust |

x |

|

x |

|

Input packaging |

x |

x |

|

|

Nylon |

x |

x |

|

|

Paper |

x |

x |

|

|

Cardboard |

x |

x |

|

|

Remains from industrial processing of fish, lobster, conch and oyster shells |

x |

x |

x |

|

Disused parts |

x |

x |

|

|

Source: Prepared by the authors

Paper, cardboard, and nylon residues, as well as containers that are not recycled or are not used in other areas, are transferred to the Raw Materials Company. Nylon residues from the whole lobster process is reused to make rope for fishing gear for the boats.

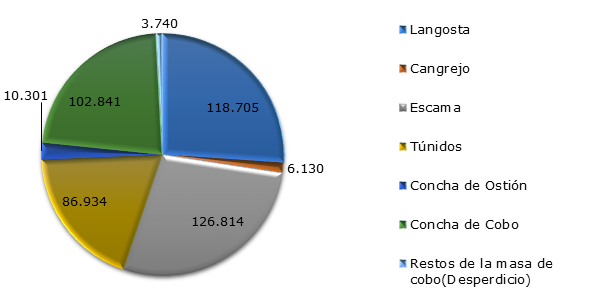

The industrial process generates a large number of residues from industrial production. Figure 2 shows the number of residues generated in the organization in the years 2022, 2023 and until April 2024, where the residues generated by conch and oyster shells, resulting from the production process to obtain the dough, stands out in third place.

Figure 2. Number of residues generated in the years 2022, 2023 and until April 2024 in

tons in the UEB industry

Source: Prepared by the authors and taken from production closures of Industrial

Fishing Company La Coloma

It is shown that the company generates solid residues from industrial processes, evidencing that during this period it generated 455,466 tons.

All these industrial residues from the productive processing of lobster and fish have established recovery processes and investment projects, the organization carries out a series of productions, taking advantage of some residues generated in various processes. Table 2 below shows the number of tons obtained from the residues generated.

Table 2. Productions obtained from by-products of some processes (2022, 2023 and until April 2024, in tons)

New products |

Residues used |

2022 |

2023 |

2024 (April) |

Total |

Lobster Juice and Sauce Preserves |

Lobster cooking water |

1,980 |

1,790 |

0 |

3,770 |

Lobster Pulp |

Lobster head |

10,940 |

10,502 |

3,920 |

25,362 |

Raw Lobster Head |

Lobster head |

0 |

0 |

2,620 |

2,620 |

Fish roe |

Fish and tuna |

0 |

0,350 |

0 |

0,350 |

Fish liver |

Fish and tuna |

0 |

0,150 |

0 |

0,150 |

Waste |

Remains of fish production |

24,650 |

25,650 |

3980 |

54,280 |

Animal protein |

Remains of fish production |

1,350 |

0000 |

0 |

1,350 |

Total |

87,882 |

||||

Source: Prepared by the authors and taken from production closures of Industrial Fishing Company of La Coloma

The table above shows the products obtained from the residues generated in the lobster and flake production processes, turning them into a new source of income and productive chains. This is in response to the fact that measures are taken with the residues that is most generated in the company

It is evident that the company has the solution to the residues from the most generating processes, although it is still insufficient.

The table also shows that the number of residues generated in the organization in the period under analysis decreased by 87,882 tons, representing 19.30% of the total generated, for which the company received economic, social and environmental benefits.

Figure 2 shows the quantities of residues from conch and oyster processing. These residues are found outdoors on the UEB Industry dock, and are an imminent source of contamination, causing bad odors, proliferation of vectors and negatively impacting the organization's corporate image.

Table 3 shows the industrial production of conch mass and real oyster mass for the period from 2022 to the first quarter of 2024.

Table 3. Actual industrial production of conch mass and oyster mass

Productions |

2022 |

2023 |

2024 |

Real (t) |

Real (t) |

Real (t) |

|

Oyster mass |

0,056 |

0,395 |

0,625 |

Cobo mass |

3,618 |

4,658 |

2,418 |

Total |

3,674 |

5,053 |

3,043 |

Source: Prepared by the authors and taken from production closures of Industrial Fishing Company of La Coloma

The above data show that in the year 2023 the production of conch and oyster mass increased with respect to the year 2022 by 1,379 tons, and that the production of oyster mass through April 2024 increased by 0,230 tons with respect to 2023.

Table 4 shows the actual amounts of residues generated in the processes of obtaining conch and oyster mass in the years 2022 and 2023, including up to April 2024. The total residues generated in these productions was 116,882 tons, representing 25.66 % of the total residues, being the third after flake and lobster residues in being among the most generators and is not taken advantage of.

Table 4. Actual number of residues generated in the process of obtaining conch and oyster mass.

Residues |

2022 |

2023 |

2024 |

Real (t) |

Real (t) |

Real (t) |

|

Oyster shell |

1,086 |

7,663 |

1,552 |

Conch shell |

25,225 |

43,225 |

34,391 |

Remains of the conch mass (residues) |

1,085 |

1,397 |

1,257 |

Total |

27,396 |

52,285 |

37,201 |

Source: Prepared by the authors based on industrial indicators established for each product of Industrial Fishing of La Coloma

To obtain one ton of conch mass, 13.5 tons of conch with its shell need to be caught, and to obtain one ton of oyster mass, 20.4 tons of oyster with its shell need to be caught, which means that shell residues is generated in large volumes, making it necessary to manage and use it.

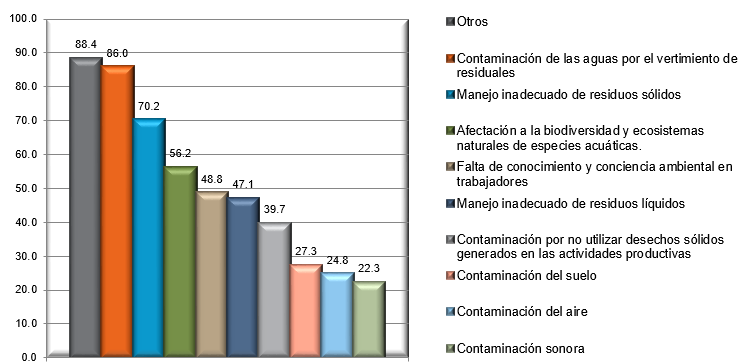

In the analysis of the primary sources, the survey was applied to specialists and workers, which was aimed at identifying the level of knowledge about environmental issues, as well as whether they considered themselves as polluting agents. It was inquired about the possible environmental problems caused by UEB Industry to the environment, the level of knowledge of environmental regulations of UEB Industry workers, the actions carried out to prevent or solve such problems and whether they had any experience in finding solutions to them.

Sixty-eight of those surveyed stated that their level of knowledge about environmental issues is scarce, so it is perceived that actions should be taken in terms of training so that each worker understands and becomes aware of it. It is the responsibility of all humans to safeguard the natural environment of which we are a part.

Regarding UEB Industry's activity and its impact on the environment, 47.1% say that it has a negative impact, which shows that the main cause of contamination is the dumping of solid residues, caused by conch and oyster shell residues. 45.5% say that it does not pollute and 12.4% say that they do not know.

Regarding the respondents' perception of whether they have a negative impact on the environment, 81.8% said no, because they care for and protect the environment, do not pollute the sea, comply with established rules and regulations, and help to improve the environment through volunteer work and coastal cleanup. The 9.9% of respondents affirmatively, which shows that they are aware that they are part of the environment and that by the simple fact of not promoting and carrying out actions in the company they feel they are polluting agents.

Among the main environmental problems identified, the 88,4 % of those surveyed stated that there was another environmental problem not identified in the selection, as they indicated in the other option that they generated large amounts of shell residues from conch and oyster production. Next, 86% stated that there is water contamination due to residues dumping and 70.2% that solid residues are handled inadequately. Figure 3 reflects this.

Figure 3. Environmental problems caused by activities at the Coloma Complex

Source: Prepared by the authors

As part of the actions carried out at UEB Industry to prevent and/or solve environmental problems and contribute to the care and protection of the environment, 96.7% of the workers state that cleaning and sanitization work is the most common, 85.1 % state that repairs and maintenance are carried out, 57.9% state that training activities are carried out and 38.8% of the workers recognize that the company carries out actions to make the best use of residues.

On the other hand, 53.7% of those surveyed stated that they had had some experience in the search for solutions to environmental problems at UEB Industry. This is related to the participation of workers in cleaning and sanitizing actions. The 46.3 % of the respondents stated that they had not.

Regarding knowledge of the environmental regulations associated with the activities carried out, 40.5 % of respondents said they were aware of some regulations, 32.2% said they were, while 27.3 % were unaware of them.

The interviews were conducted with the 7 managers that make up the UEB Industry. The application of this instrument made it possible to identify, according to the perception of the managers, the environmental problems that exist, the activities that cause these problems and the actions that are carried out to solve them. It also made it possible to assess the degree of knowledge regarding environmental regulations according to their activity.

From the processing of the survey it is conclude that:

The main results of the characterization of the solid residues generated in the UEB Industry are as follows:

The residues generated in industrial processes are multiple, hence the need to manage them with a systemic and circular approach. The use of these residues depends on existing technologies and the training of the economic agents that interact in the ecosystem.

Silva et al. (2019) state that calcium carbonate can be derived from marine debris, such as crustaceans and bivalve shells and is one of the most used raw materials in various industries, such as construction materials, food supplements, pharmaceuticals, animal feed, plastic production. It can be used for tables and workbenches, for home decoration, for laboratory benches, for industrial kitchens, among other potential uses. The authors presented a business solution for the reuse and recycling of oyster shells.

The literature reports that laboratory tests have been carried out to establish the best operating conditions for obtaining calcium lactate and citrate at laboratory scale from oyster shell meal, as reported by Curbelo Hernández et al. (2021). The authors state that the accumulation of oyster discards or shells has a negative environmental impact due to their slow degradation, and the potential of these residues for obtaining calcium salts has been demonstrated.

Topiæ Popoviæ et al. (2023) state that mollusk shells can be used to produce gypsum or green cement which is mainly used in interior applications due to its low resistance to water and cracking. Its thermal and sound insulation and fire resistance make it one of the most widely used building materials. They argue that shells are therefore an important by-product, which should not become residues, but rather a new raw material to be used to its full potential.

The study conducted by Rodriguez et al. (2022) evidences and validates that oyster shell meal can replace 100% of the calcium carbonate used in the feed of laying hens and that the preparation of this meal constitutes an alternative (added value) to the oyster production process, which in some localities will be important to reduce the negative effect that this residues can generate if it is not given an alternative use.

Shells are therefore an important by-product, which should not become residues, but rather a new raw material to be used to its full potential (Topiæ Popoviæ et al., 2023).

The development of alternatives for the valorization of residues generated in the conch and oyster production process will generate the opportunity to create new jobs, income and increase the awareness of its workers, contributing to the development of the company and, therefore, of the locality, as evidenced by the scientific literature consulted.

These studies and bibliographic references demonstrate the technical, economic, social and environmental feasibility of the proper management of solid residues from conch and oyster processing. The UEB Industry of the Industrial Fishing Company La Coloma should promote this management to minimize the pollution that is generated, which threatens the health of workers and the environmental performance of the Organization and, in turn, its possible recovery, transforming it into an opportunity to increase its added value, generate economic benefits to its workers and, therefore, contribute to the development of the locality.

The industry in La Coloma produces shell residues each year that is still disposed of in dumps due to the lack of a technically feasible, environmentally sustainable and economically profitable recycling alternative. Conch and oyster shells are a potential raw material for obtaining calcium salts, which can be used for animal feed in the province.

The characterization of the conch and oyster production process and its solid residues during the years 2022, 2023 and until April 2024 revealed that the company generated 455.5 tons of solid residues from the industrial process, of which 116.9 tons corresponded to oyster and conch shells and are not reused, as well as it was also found that there is insufficient training and awareness of workers on environmental issues.

The study demonstrated the need to strengthen the integrated management and proper handling of these solid residues from the industrial process, which, in turn, would increase their added value and minimize their environmental impact, contributing to the sustainable development of the locality.

REFERENCES

Aranda Usón, A., & Zabalza Bribián, I. (2010). Ecodiseño y análisis de ciclo de vida. Prensas de la Universidad de Zaragoza. https://puz.unizar.es/1121-ecodiseno-y-analisis-de-ciclo-de-vida-serie-eficiencia-energetica.html

Asamblea Nacional del Poder Popular. (2022). Ley del Sistema de los Recursos Naturales y el Medio Ambiente (Ley 150). Gaceta Oficial de la República de Cuba, Edición Ordinaria No. 87. https://www.gacetaoficial.gob.cu/es/ley-150-de-2022-de-asamblea-nacional-del-poder-popular

Citma. (2021). Estrategia Ambiental Nacional 2021-2025. Ministerio de Ciencia Tecnología y Medio Ambiente. https://www.citma.gob.cu/estrategia-ambiental-nacional/

Curbelo Hernández, C., Cruz Ponce, S., Ortega Piloto, L., Sotolongo Valdés, E. A., Sáez Sigarroa, B., & Fumero Acosta, Y. (2021). Obtención de sales de calcio a partir de conchas de ostiones a escala de laboratorio. Revista Cubana de Investigaciones Pesqueras, 38(1), 7-15. http://repositorio.geotech.cu/xmlui/handle/1234/5226

de Miguel, C., Martínez, K., Pereira, M., & Kohout, M. (2021). Economía circular en América Latina y el Caribe: Oportunidad para una recuperación transformadora. Comisión Económica para América Latina y el Caribe. https://www.cepal.org/es/publicaciones/47309-economia-circular-america-latina-caribe-oportunidad-recuperacion-transformadora

Florez Jalixto, M. A., Roldán Acero, D. J., Omote Sibina, J. R., & Molleda Ordoñez, A. A. (2021). Biofertilizantes y bioestimulantes para uso agrícola y acuícola: Bioprocesos aplicados a subproductos orgánicos de la industria pesquera. Scientia Agropecuaria, 12(4), 635-651. https://doi.org/10.17268/sci.agropecu.2021.067

González Zevallos, D. R., Góngora, M. E., & Durán Romero, C. (2020). Abordaje socioambiental con énfasis en los residuos sólidos generados por la flota pesquera de Rawson, Patagonia Argentina. Interciencia, 45(3), 142-149. https://www.interciencia.net/wp-content/uploads/2020/03/03_6401_A_Gonzalez_Zevallos_v45n3_8.pdf

Martínez Álvarez, O. (2011). Estado actual del aprovechamiento de subproductos de la industria pesquera mediante la obtención de productos de alto valor añadido. Alimentaria: Revista de tecnología e higiene de los alimentos, (429), 71-80. https://dialnet.unirioja.es/servlet/articulo?codigo=3823579

Onudi. (2020). Manual de producción más limpia. Introducción a la producción más limpia. Organización de las Naciones Unidas para el Desarrollo Industrial. https://www.unido.org/sites/default/files/2008-06/1-Textbook_0.pdf

Paredes Concepción, P. (2014). Producción más limpia y el manejo de efluentes en plantas de harina y aceite de pescado. Industrial Data, 17(2), 72-80. https://doi.org/10.15381/idata.v17i2.12050

PNDES. (2019). Plan Nacional de Desarrollo Económico y Social hasta el 2030. Plan Nacional de Desarrollo Económico y Social. https://www.mep.gob.cu/sites/default/files/Documentos/Archivos/FOLLETO%20PNDES%20%20FINAL%20est%C3%A1%20en%20planificaci%C3%B3n.pdf

Rodríguez, B., Arencibia Carballo, G., Gutiérrez, O., Betanzos Veja, A., Pis, M. A., Ocano, C. A., & Navarro García, G. (2022). Viabilidad de sustitución del carbonato de calcio por polvo de conchas de ostión (Crassostrea spp) en dietas para gallinas ponedoras, Cuba. Brazilian Journal of Animal and Environmental Research, 5(3), 2922-2933. https://doi.org/10.34188/bjaerv5n3-026

Segura, Á. M., Rojas, L. A., & Pulido, Y. A. (2020). Referentes mundiales en sistemas de gestión de residuos sólidos. Revista ESPACIOS, 41(17). https://es.revistaespacios.com/a20v41n17/20411722.html

Silva, T. H., Mesquita Guimarães, J., Henriques, B., Silva, F. S., & Fredel, M. C. (2019). The Potential Use of Oyster Shell Waste in New Value-Added By-Product. Resources, 8(1), 13. https://doi.org/10.3390/resources8010013

Terry Berro, C. C. (2005). Enfoque actual de las iniciativas en producción más limpia y sus proyecciones en el ámbito nacional. Cub@: Medio Ambiente y Desarrollo, 5(9). https://cmad.ama.cu/index.php/cmad/article/view/75

Topiæ Popoviæ, N., Lorencin, V., Strunjak Peroviæ, I., & Èož Rakovac, R. (2023). Shell Waste Management and Utilization: Mitigating Organic Pollution and Enhancing Sustainability. Applied Sciences, 13(1), 623. https://doi.org/10.3390/app13010623

Conflict of interest

Authors declare that they have no conflicts of interest.

Authors' contribution

Cirelys Correa Carmona and Susana Díaz Aguirre designed the study, analyzed the data and prepared the draft.

Cirelys Correa Carmona, Susana Díaz Aguirre and Ray Leonard Sánchez Ramírez were involved in the collection, analysis and interpretation of the data.

All the authors reviewed the writing of the manuscript and approve the version finally submitted.