0000-0001-7817-9301

0000-0001-7817-9301  uvecinorondon@gmail.com

uvecinorondon@gmail.comGisela María Estrada Bazán2

0000-0002-8386-3439

0000-0002-8386-3439  egisela238@gmail.com

egisela238@gmail.comAdrián Cánova Herrandiz1

0000-0001-6882-6149

0000-0001-6882-6149  adriancanova434@gmail.com

adriancanova434@gmail.com

Cooperativismo y Desarrollo, May-August 2024; 12(2), e683

Translated from the original in Spanish

Experience of good practices

Cooperative development actions in the tannery mini-industry: contributions in "Arte del Cuero"

Acciones de desarrollo cooperativo en la minindustria de tenería: aportes en "Arte del Cuero"

Ações de desenvolvimento cooperativo na mini-indústria de curtumes: contribuições na "Arte del Cuero"

Uliser Vecino Rondon1  0000-0001-7817-9301

0000-0001-7817-9301  uvecinorondon@gmail.com

uvecinorondon@gmail.com

Gisela María Estrada Bazán2  0000-0002-8386-3439

0000-0002-8386-3439  egisela238@gmail.com

egisela238@gmail.com

Adrián Cánova Herrandiz1  0000-0001-6882-6149

0000-0001-6882-6149  adriancanova434@gmail.com

adriancanova434@gmail.com

1 University of Latin America, Xalapa campus. Mexico.

2 Food Production Company. Meat UEB "Abel Santamaría Cuadrado". Isla de la Juventud, Cuba.

Received: 10/11/2023

Accepted: 7/06/2024

ABSTRACT

The tanning industry needs to implement changes and adopt innovative technologies to guarantee efficient management, focused on environmental, social and economic sustainability. The work was carried out in 2022, in order to propose improvements to the "Leather Art" project on the Isla de la Juventud, especially to treat the cattle skins generated in the "Abel Santamaría Cuadrado" Meat-Based Business Unit. Data collection was carried out through various sources, including the production technology area, interviews with mini-industry producers and the "Abel Santamaría" Meat-Based Business Unit, as well as through direct observations of technological processes. Among the problems identified are: difficulties in processing, obsolete equipment, insufficient capacity, limited transportation and lack of economic study. Among the highlighted results, the need to coordinate with livestock production units for the care and marking of animal skins is emphasized, thus guaranteeing the optimal use of all available hides. Fulfillment of the objective not only yielded concrete results, but was also involved in the promotion of leather processing through a mini-tannery industry, with the collaboration of local actors to strengthen the project. Specific actions were proposed that not only improved the efficiency and sustainability of the production process, but also guaranteed the availability of raw materials at the local level to consolidate the project as a reference for the use of skins generated by the meat industry.

Keywords: local actors; productive and industrial dynamics; cattle; leather processing; tannery.

RESUMEN

La industria curtidora necesita implementar cambios y adoptar tecnologías innovadoras para garantizar una gestión eficiente, enfocada en la sostenibilidad ambiental, social y económica. El trabajo se desarrolló en el año 2022, con el fin de proponer mejoras al proyecto "Arte del Cuero" en la Isla de la Juventud, especialmente para tratar las pieles de ganado vacuno generadas en la Unidad Empresarial de Base Cárnico "Abel Santamaría Cuadrado". La recopilación de datos se realizó a través de diversas fuentes, incluyendo el área de tecnología de producción, entrevistas a los productores de la minindustria y a la Unidad Empresarial de Base Cárnico "Abel Santamaría", así como mediante observaciones directas de los procesos tecnológicos. Entre los problemas identificados se encuentran: dificultades en procesamiento, equipamiento obsoleto, capacidad insuficiente, transporte limitado y falta de estudio económico. Entre los resultados destacados, se enfatiza la necesidad de coordinar con las unidades productivas pecuarias para el cuidado en el marcaje de las pieles de los animales, lo que garantiza así la utilización óptima de todos los cueros disponibles. El cumplimiento del objetivo no solo arrojó resultados concretos, sino que también se implicó en la promoción del procesamiento de pieles mediante una minindustria de tenería, con la colaboración de actores locales para fortalecer el proyecto. Se propusieron acciones específicas que no solo mejoraron la eficiencia y sostenibilidad del proceso productivo, sino que también garantizaron la disponibilidad de materia prima a nivel local para consolidar así el proyecto como un referente para el aprovechamiento de las pieles generadas por la industria cárnica.

Palabras clave: actores locales; dinámica productiva e industrial; ganado vacuno; procesamiento de pieles; tenería.

RESUMO

A indústria de curtumes precisa implementar mudanças e adotar tecnologias inovadoras para garantir uma gestão eficiente, com foco na sustentabilidade ambiental, social e econômica. O trabalho foi desenvolvido no ano de 2022, com o objetivo de propor melhorias para o projeto "Arte do Couro" na Ilha da Juventude, especialmente para o tratamento de peles bovinas geradas na Unidade de Negócios de Base de Carne "Abel Santamaría Cuadrado". A coleta de dados foi realizada por meio de várias fontes, incluindo a área de tecnologia de produção, entrevistas com produtores da mini-indústria e da Unidade Empresarial de Base Cárnica "Abel Santamaría", bem como por meio de observações diretas dos processos tecnológicos. Entre os problemas identificados estavam: dificuldades de processamento, equipamentos obsoletos, capacidade insuficiente, transporte limitado e falta de estudos econômicos. Entre os resultados destacados estava a necessidade de coordenar com as unidades de produção de gado para assegurar que as peles dos animais sejam cuidadosamente marcadas, garantindo assim o uso ideal de todas as peles disponíveis. A realização do objetivo não só produziu resultados concretos, mas também envolveu a promoção do processamento de peles por meio de uma indústria de mini curtumes, com a colaboração de atores locais para fortalecer o projeto. Foram propostas ações específicas que não só melhoraram a eficiência e a sustentabilidade do processo de produção, mas também garantiram a disponibilidade de matéria-prima em nível local para consolidar o projeto como uma referência para o uso de peles geradas pela indústria de carnes.

Palavras-chave: atores locais; dinâmica produtiva e industrial; gado; processamento de couro; curtume.

INTRODUCTION

Industrial development has caused the transformation of the environment in different ways, thus changing the nature and degree of the environmental impacts of the dissimilar activities carried out. The depletion of natural resources, the pollution of water, air and soil, are typical current examples. These activities can be cumulative and synergistic over time (Gopalakrishnan et al., 2022).

The divorce between the productive management of the organization and the management of environmental protection has as a consequence a negative impact on the technical, economic and environmental orders, since the appearance of technological indiscipline and unnecessary consumption of raw materials and energy leads to unnecessary generation of waste derived from industrial activity, which causes damage to the environment (Betancourt Chávez et al., 2023).

For their part, Shi et al. (2021) state that it is important to point out that if actions are concentrated only on minimizing waste generation, the effort triggers profound changes in the industry, which not only affect the way of producing, but also have an impact on the selection of social objectives, in the research and development processes of new products, in the commercial strategy, in the organizational schemes, and in the management and control systems, thus demonstrating the close link between the quality management approach, the environmental and the analysis of processes to achieve adequate global performance of the industry.

The tanning industry, which transforms skin into leather for different uses, is by nature highly consuming of water and generating waste that is aggressive to the environment, difficult to treat as a whole due to the varied range of chemicals used to carry out this process. transformation. This industry also does not escape the general trend of focusing efforts on productive management to the detriment of the environment (Kalenatic et al., 2009).

The Isla de la Juventud has the "Abel Santamaría Cuadrado" Meat Base Business Unit (UEB in Spanish), an entity in which farm animals that are exploited under the production conditions in the territory are industrially slaughtered. An average of 60 heads of cattle are processed weekly, destined for social consumption. The problematic situation presented by the following research is due to the fact that these slaughters generate cattle skins as by-products, which constitute an important source of financing for the closure of the production cycle. However, at the end of 2022, 739,733 kg of skin had been seized, which caused a loss of $1,980,996.24 CUP (Minag, 2022).

The industry annually generates around 2,000 units of leather, which undergo a conservation process with common salt and are deposited in an area designated for this purpose. Due to rejection due to bites, holes and deep scratches, losses range between 8 and 9%, and it has been stated that the leather is selected by age, those of greatest interest to the tannery are the youngest animals. According to the criteria of specialists, this confiscation figure is acceptable, however, it implies the loss of more than 30 thousand skins per year, if it is taken into account that for the country the export of a thousand salted skins is equivalent to $3,400 dollars approximately, it is lossing an important resource that can generate significant income to the local economy.

Through direct observation, it has been possible to evaluate that the storage conditions of this material and the insufficient variants for the use of the skins have generated losses such as non-edible use, which become contaminated in the treatment areas. These process wastes are lost due to lack of adequate technology for their processing. Previously, these materials were transferred to Havana City for closing the cycle. There are three Cuban standards (NC 2820:2003; NC 2821:2003; NC 464:2007), which govern the entire technological process from the point of view of quality, the presentation of the leathers, their selection by weight and conservation, which have not always been applied rigorously.

Since 1994, a non-governmental Cuban cultural project has been conceived, "Arte del Cuero" (PAC in Spanish), conceived by the artisan Fidencio Elpidio Rubio Leyva, it was created for manual and applied arts, to the manifestation of leathers. Made up of artists, curators, critics, researchers, historians, communicators and specialists from various areas, they collaborated to carry out projects with similar objectives. These projects arise from the group in pursuit of local development in the special municipality of Isla de la Juventud, as well as initiatives at the national and international level.

The objective was to propose improvements to the "Arte del Cuero" project on the Isla de la Juventud, which contributes to treating the cattle skins generated at the "Abel Santamaría Cuadrado" Meat UEB.

MATERIALS AND METHODS

The research was carried out on the Isla de la Juventud in 2022. The data is obtained from the production technology area, from the interviews applied to the producers of the mini-industry and from the UEB Cárnico "Abel Santamaría", as well as direct observation to technological processes.

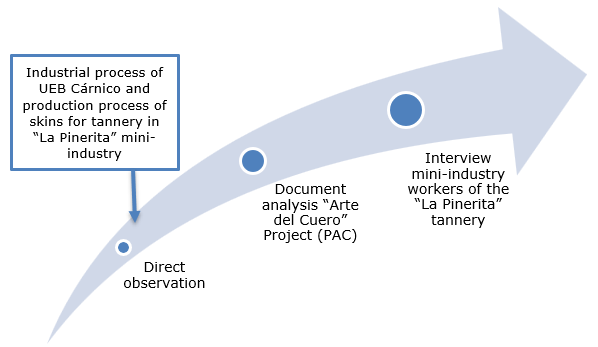

To understand the dynamics of this process, the common thread of the productive and industrial process is proposed in figure 1.

Figure 1. Driving thread of the productive and industrial process

Source: Own elaboration

RESULTS AND DISCUSSION

The development of the tannery industry

The bovine leather industry is an industry that is going through a critical social and economic crisis. Leather is currently being replaced by synthetic products in a similar way and at a low cost according to criteria mentioned by some leather producers; the aim is to help it grow stronger and bigger than any other production, since with the technology applied in the race, prices can be lowered and quality improved (Nagi et al., 2020).

Unborn skins are commercially more valued nationally and worldwide due to their high quality since, the younger the animal is at the time of slaughter, the softer and more delicate the structure of the flower will be and the lower the probability of deterioration due to scratches, parasites, ringworm, manure contamination, incorrect skinning or inadequate salting (Natarajan & Manivasagan, 2018).

Chojnacka et al. (2021) indicate that the skin is softer and more delicate when the animal is slaughtered at a young age, reducing the probability of deterioration. The skin of a female normally has a finer grain than that of a male and has a looser fiber structure and a softer and more elastic leather is obtained. Likewise, it states that the industrialization of unborn skins refers to unborn offspring that may be male or female of female cattle. In unborn skin, the grain layer has at least a thickness that is half the total thickness of the skin. The reticular layer is in a state of development and represents the other half. These skins have a very fine grain because the skin pores are smaller and, furthermore, because the animal is very young, its grain has very few defects.

Bai et al. (2022) explain that the skin is an external structure of animal bodies. It is a heterogeneous substance generally covered with hair or wool and formed by several overlapping layers. This external envelope exerts a protective action, but at the same time it also fulfills other functions such as: Regulating body temperature, eliminating waste substances, housing sensory organs that facilitate the perception of thermal, tactile and sensory substances, storing fatty substances, they protect the body from the entry of bacteria. The skin responds to the physiological changes of the animal, reflecting many important and specific characteristics such as: age, sex, diet, environment, state of health.

For his part, Silva (2021) indicates that the skin recovered by skinning from slaughtered animals is called fresh skin or green skin. In fresh skin there are quite different structural zones in terms of thickness and capacity. These contrasts are especially important in the case of large bovine skins. Three areas are distinguished in the skin: the croup, the neck and the skirts.

In a skinned skin, three very different areas can be distinguished: a neck, a croup and two skirts (Carril Verastegui et al., 2023). The crupon represents approximately 45% of the total fresh skin, and of the three parts it can also be said to be the most homogeneous and compact. The neck has a weight of approximately 25% of the total fresh skin and is a part of the skin that has many wrinkles. The skirts have a weight of approximately 30% of the total fresh skin, and they are also the most flabby and irregular parts of the skin.

Tanning procedure

Mayta and Mayta (2017) mention that hides and skins arrive at the tannery in different states of conservation and warehouses must be prepared for the type of skins they must receive. Upon receipt of a batch of skins, the weight, quality of the skins received and any shrinkage must be controlled. Soaking is the first operation to which the skins are subjected in manufacturing and consists of treating them with water in a tub or drum. The purpose of soaking is to clean the hides of all foreign matter. The complexity of the soaking operation depends fundamentally on the conservation method. Fresh skins do not need soaking per se, but rather a thorough washing to clean the skin, removing blood, lymph and excrement.

It is confirmed that taking into account the impurities contained in the skin and the salt that in some cases accompany it, it is considered that the hardness of the water should have little influence on the soaking operation. If possible, water that is free of organic material and especially bacteria should be used. When soaking a skin containing 12.5% common salt and 44.5% humidity with 100% water, it turns out that the concentration of the residual bath in equilibrium will be 8% common salt, if it is wanted to completely eliminate salt from a skin, the bath must be changed repeatedly.

Fur and lime

Anchatipán Bastidas and Flores Tapia (2023) ensure that properly hydrated skin, clean and with parts of its proteins eliminated in soaking, goes on to the peeling operations, whose double mission lies in removing the epidermis with the hair from the corium and loosening the fibrous structure of collagen in order to adequately prepare for tanning processes.

Deliming

Agustini et al. (2020) describes deliming as the operation that serves to eliminate lime and alkaline products from the interior of the leather and, therefore, the elimination of alkaline swelling from the matted leather.

Raw

Gebremariam et al. (2023) say that the main object of this operation is the cleaning of the skin, eliminating the subcutaneous and adipose tissue, which must be removed in the first stages of manufacturing in order to facilitate the penetration of the chemicals applied in later phases and have as regular a thickness as possible for the proper performance of the operations that follow. The most appropriate state for fleshing is with the skin encased due to its constitution.

Tanning

At this stage, the skin or leather is treated with mineral or vegetable agents that combine with collagen, transforming it into tanning. Chromium tanning according to Puente Guijarro (2019) is achieved using soluble chromium salts, primarily chromium sulfate. Chrome tanning today represents one of the most used techniques for tanning leather, due to its quality and the short duration of the process compared to vegetable tanning. For this, chromium salts are used to produce a green/light blue leather. heat-resistant.

Vegetable tanning

Tanning with vegetable tanning agents is obtained using vegetable materials derived from the bark or wood of trees and other various plants, which produce a light hazelnut-colored tanning, used mainly for shoe soles and leather goods. Unique vegetable tanning, carried out in past centuries, has been completely replaced by chrome tanning, however, it is still used for shoe soles, saddles and for some technical tanning. Vegetable tanning is a very long process that can last from one day (in drums) to several weeks (in vats) (Estévez Bonilla & Paredes Cruz, 2018).

Drained

According to Vargas Doria Medina and Amurrio Derpic (2017) they mention that this process consists of eliminating excess water, it can be done using two methods:

Divided

Martínez Buitrago and Romero Coca (2017) indicate that the purpose of dividing is to divide into two layers, which are called the grain layer, which is used for the manufacture of grain leather, and the flesh or rasp layer, which is used for the manufacture of chamois and flesh.

Grease

According to Mainardi Remis et al. (2021), in the fibers of tanned leather, moisture moves easily since it is a fairly flexible material. When the skins dry, the body can become hard because the fibers have dehydrated and joined together, forming a compact substance. The greasing operation is carried out in order to obtain a leather that is softer to the touch, which is achieved with the incorporation of fatty materials that are soluble or not in water. Its main function is to separate the fibers and lubricate them so that they cannot slide. easily one in relation to another.

Alternatives to strengthen the tannery industry

In the leather industry, especially in those companies whose standardization has not been established, seek to improve quality techniques in order to obtain a softer, more flexible and resistant leather, here is the importance of acquiring this information to improve quality techniques. The main characteristic of chromium sulfate on unborn skin is to increase resistance to tearing, rupture of fibers, friction when stretched, preserving softness and delicacy; by virtue of which the following objectives were raised: Use chromium sulfate in the tanning of unborn bovine skin, in addition three levels of chromium sulfate (7, 8, 9) were tested in the tanning of unborn bovine skins (Amancha Proaño & Jaramillo Constante, 2022).

This factory produces leather for soles, from beef butt, and its tanning process is based on the use of vegetable tannins with tannin content, its production focuses on obtaining pickled butt. From the analysis of the process, the main factors impacting the environment were determined and are listed below (Estévez Bonilla & Paredes Cruz, 2018):

Risk prevention is necessary in every workplace, including craft workshops and cooperatives; the employer or his/her representative must take measures to reduce occupational risks, which must be based on the guidelines on occupational health and safety management systems. To this end, risk prevention plans will be developed in workplaces that will be made known and will contemplate, at least, the following actions (Nagi et al., 2020):

Results of the observation guide applied at the UEB Cárnico "Abel Santamaría"

From the analysis carried out of the observation guide applied to the processing of skins at the UEB Cárnico, the following were obtained:

Results of the Observation Guide applied to tannery workers

The state in which the skins are obtained from industrial processing at the UEB Cárnico was evaluated; the following was obtained from the instrument:

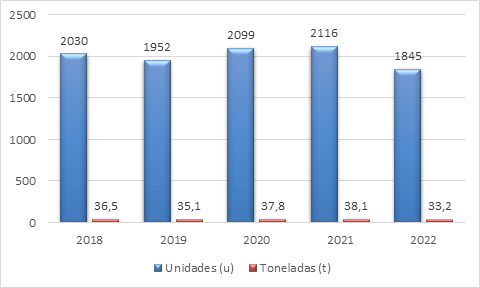

During the period between 2018 and 2022, as seen in figure 2, leather production was distributed as follows: in 2018, 2,030 units and 36.5 tons were reached, in 2019, 1,952 units and 35. 1 tons, in 2020, 2099 units and 37.8 tons were produced, in 2021 it rose to 2116 units and 38.1 tons and, finally, in 2022, 1845 units were reached, adding a total of 33.2 tons of leather.

Figure 2. Number of leathers obtained during the years 2018-2022

Source: Own elaboration

Results of the interview applied to the tannery workers

On the Isla de la Juventud, since 1989, a work team has been working on the skin processing line. In 1994, the Júcaro tankage factory was used until 2008, when the activity was suspended due to the losses generated by the Gustav meteorological phenomenon. In 2013, the idea of leather processing was rescued, which since 2016 has been strengthened through the "Arte del Cuero" (PAC) project, developed by two self-employed workers, in the "La Pinerita" mini-industry.

Results of the documentary analysis of the review of the "Arte del Cuero" (PAC) project on the Isla de la Juventud

The project is directed by Fidencio Elpidio Rubio Leyva and has an artistic-educational-community character, with an important social and community character, promoting values such as generosity, love and the will to do the common good, in an act in which that by transforming the community they transform themselves into better social beings, and is anchored in the technologies of ceramics and bronze, based on creation.

The main objective of the "Arte del Cuero" Project (PAC) is to consolidate itself as a reference in the special municipality, promoting artistic creation and providing a space for cultural exchange that transcends local and national borders. It is sponsored by the Municipal Government, the Gerona Norte Popular Council and the Art with Fire Project of the plastic artist Antonio Manuel Lewis Belgrove.

It has eight objectives, including: promoting participation, exchange, highlighting talent and creativity, with the use of local materials, under the principle of leather techniques; producing means of individual protection for fishermen who, when catching bonito, require the use of a cape, protective sleeves and a pole belt, which are imported. Another client is the Etecsa Company, which is offered tool belts to facilitate the work of linemen and their safety, which are affected by the limitations for their acquisition and their approximate prices in the international market are 50 USD and 55 USD respectively.

From the analyzes carried out by the work team, it was identified that it is necessary to declare the actions to promote productive chains between the entities that can strengthen the realization of the idea, as well as define, in the search for financing, the economic feasibility of the project and the incorporation of other national actors that contribute to closing the cycle according to the proposed objectives.

Actions to improve the "Arte del Cuero" (PAC) project on the Isla de la Juventud

To respond to the general objective, the work team proposes actions to enhance the use of the skins generated from the industrial process. The actions are concentrated in two scenarios: the tannery industry and the mini-industry (Table 1).

Table 1. Actions to improve the "Arte del Cuero" (PAC) project on the Isla de la Juventud

Industry |

Mini-industry |

Maintain vigilance over the animal slaughter process to promote the quality of the skin extracted from the animals. |

Guarantee that the area has the necessary biosecurity for the processing of the skins. |

Guarantee prior disinfection of the slaughter area and the necessary means for transporting the skins. |

Guarantee the purchase of common salt to salt the skins. |

Ensure that the animals' skin and paws are showered to remove impurities. |

Perform the resalting of the skins that are purchased and leave them to rest until they enter the production process. |

Reconcile with livestock production units the care in marking the skin of animals to guarantee the use of all inedible waste. |

Complete a development project for its socialization among the actors that can participate in the productive chain (local body of the Communist Party of Cuba, local government, university, food company, public health). |

Maintain compliance with the use of approved detergents and disinfectants for cleaning the slaughter area. |

In collaboration with the University and the Flora and Fauna Company, identify other tree species for tanning the skins. |

Maintain the quantity and quality of water necessary for the slaughter process. |

Ensure that maintenance is carried out on the equipment for the tannery. |

Guarantee the purchase of the appropriate means to make cuts to the skin of animals already slaughtered (curved knives). |

Carry out a selection process from the leather industry with quality for the tannery. |

Maintain compliance with the drainage carried out in the oxidation lagoon, the use by workers of protective means. |

Identify financing sources for the purchase and import of specialized equipment. |

Once the skins of the slaughtered animals have been removed, deflesh them, move them to an area where they are salted with common salt, stow and store them for conservation for a period of no more than three months. |

Request the economic feasibility study from the university. |

Cooperation actions between both companies |

|

Organize joint training programs aimed at workers from both industries, in order to improve technical skills and promote a cooperative approach in the handling and processing of hides. |

Promote alliances with the meat industry to share resources and knowledge, thus optimizing the skin treatment process |

Develop environmental practices and efficient use of resources collaboratively, with the aim of reducing environmental impact and promoting sustainability in both industries |

Implement a joint research and development program aimed at improving leather processing techniques, where both industries contribute resources and knowledge to innovate more effective and sustainable treatment methods. |

Establish a joint system for collecting and distributing skins generated by the meat industry to the tannery mini-industry, thus facilitating a continuous and efficient flow of raw materials for both parties. |

Establishment of a joint marketing system, which facilitates access to consolidated distribution channels in the territory and allows the connection of these products with national companies. |

Source: Own elaboration

The most feasible way to manage this type of production is through a strategic alliance between both companies. This alliance can facilitate the appointment of a member of the production area of the meat industry with the purpose of establishing and maintaining dialogue between both parties. This coordinator can facilitate collaboration in the collection and distribution of skins that is currently not feasible in a viable manner, as well as the implementation of joint training actions and the creation of a shared research and development system.

Cooperation between companies allows them to take advantage of each other's strengths, combining the efficiency and resources of the meat industry with the flexibility and innovation of the mini-industry. Added to this is that, by promoting the active participation of mini-industry workers in production management, the sense of belonging and shared responsibility is strengthened, which leads to a more sustainable and equitable development of the skins industry on the Isla de la Juventud.

A specific form of productive chain consists of establishing a continuous system where the meat industry supplies cattle skins to the mini-industry, the latter of which is responsible for processing the skins for the manufacture of leather products, such as bags, shoes and belts. For its part, the meat industry is favored because it does not have the accumulation of skins in its facilities. These manufactured products are permanently marketed due to the demand that exists with companies such as Etecsa and PescaIsla, thus creating an integrated production cycle that benefits both parties and promotes local economic development in a sustainable manner.

In the review of the literature, it was identified that the tannery industry, based on bovine leather, is going through a critical social and economic crisis; currently, leather is replaced by synthetic products in a similar way and at a low cost according to criteria mentioned by some leather producers. However, the skins continue to pollute the environment, making it necessary to search for alternatives for their use.

To optimize the use of the skins coming from the UEB Cárnico "Abel Santamaría Cuadrado" within the industrial process, it is essential to coordinate with the livestock production units to guarantee careful marking of the animals' skin. This coordination ensures maximum utilization of all available leathers.

Of the skins obtained at the UEB Cárnico "Abel Santamaría Cuadrado" as part of the industrial process, it is necessary to reconcile with the livestock production units the care in marking the skin of the animals to guarantee the use of all the leathers.

The processing of skins is being promoted through a development project in a tannery mini-industry, which needs productive links with social actors from the local level for its empowerment.

Actions were defined to improve the "Arte del Cuero" (PAC) project on the Isla de la Juventud, as a common scenario to promote the use of the skins generated in the industry. The actions respond to the responsibilities defined by both parties to guarantee the availability of raw materials for the tannery in the territory.

REFERENCES

Agustini, C. B., Da Costa, M., & Gutterres, M. (2020). Tannery wastewater as nutrient supply in production of biogas from solid tannery wastes mixed through anaerobic co-digestion. Process Safety and Environmental Protection, 135, 38-45. https://doi.org/10.1016/j.psep.2019.11.037

Amancha Proaño, P. I., & Jaramillo Constante, E. D. (2022). Obtención de pieles curtidas con taninos. Cuadernos del Centro de Estudios de Diseño y Comunicación, (176), 101-109. https://doi.org/10.18682/cdc.vi176.8613

Anchatipán Bastidas, D., & Flores Tapia, N. E. (2023). Actualidad de tratamientos y procesos de reciclaje de los residuos industriales de curtiembres en Ecuador y el mundo. Revista Tecnológica - ESPOL, 35(1), 66-87. https://doi.org/10.37815/rte.v35n1.983

Bai, Z., Wang, X., Zheng, M., Yue, O., Xie, L., Zha, S., Dong, S., Li, T., Song, Y., Huang, M., & Liu, X. (2022). Leather for flexible multifunctional bio-based materials: A review. Journal of Leather Science and Engineering, 4(1), 16. https://doi.org/10.1186/s42825-022-00091-6

Betancourt Chávez, D. G., Andrade Valdivieso, I. M., & Enriquez Veintimilla, C. E. (2023). Tratamientos de superficie en cuero para el desarrollo de accesorios para la empresa tenería San José. Revista Científica Arbitrada Multidisciplinaria PENTACIENCIAS, 5(6), 11-18. https://doi.org/10.59169/pentaciencias.v5i6.775

Carril Verastegui, B. D., Castro Vargas, D. J., Machacha-Mamani, J., Lujan Minaya, J. C., Yenque Guerrero, K. E., & Mendoza Castillo, A. L. L. F. (2023). Industrial redesign in leather tanning processes. Universidad Ciencia y Tecnología, 27(118), 109-119. https://doi.org/10.47460/uct.v27i118.692

Chojnacka, K., Skrzypczak, D., Mikula, K., Witek-Krowiak, A., Izydorczyk, G., Kuligowski, K., Bandrów, P., & Ku³a¿yñski, M. (2021). Progress in sustainable technologies of leather wastes valorization as solutions for the circular economy. Journal of Cleaner Production, 313, 127902. https://doi.org/10.1016/j.jclepro.2021.127902

Estévez Bonilla, A. E., & Paredes Cruz, R. E. (2018). Los costos ocultos y su impacto en el costo de producción del cuero en las curtidurías artesanales caso: Curtiduría Artesanal "A&L" de la provincia de Tungurahua. Revista UNIANDES Episteme, 5(Extra 1), 589-603. https://revista.uniandes.edu.ec/ojs/index.php/EPISTEME/article/view/1507

Gebremariam, E. C., Malede, Y. C., Prabhu, S. V., Varadharajan, V., Manivannan, S., Jayakumar, M., & Gurunathan, B. (2023). Development of bio-based adhesive using tannery shaving dust: Process optimization using statistical and artificial intelligence techniques. Bioresource Technology Reports, 22, 101413. https://doi.org/10.1016/j.biteb.2023.101413

Gopalakrishnan, B., Muthukumarapandian, A., Sujatha, S., Raja, S., Rajamohan, N., & Rajasimman, M. (2022). Statistical modeling and optimization of tannery wastewater treatment in a fluidized bed bioreactor with low density biomass support. Modeling Earth Systems and Environment, 8(1), 1099-1107. https://doi.org/10.1007/s40808-021-01143-2

Kalenatic, D., López Bello, C. A., & González Rodríguez, L. J. (2009). Modelo de ampliación de la capacidad productiva. Ingeniería, 14(2), 67-77. https://revistas.udistrital.edu.co/index.php/reving/article/view/2381

Mainardi Remis, J. M., Gutiérrez Cacciabue, D., Romero, D. S., & Rajal, V. B. (2021). Setting boundaries within a bottled water plant aid to better visualize the water use: An approach through the water footprint indicator. Journal of Water Process Engineering, 43, 102199. https://doi.org/10.1016/j.jwpe.2021.102199

Martínez Buitrago, S. Y., & Romero Coca, J. A. (2017). Revisión del estado actual de la industria de las curtiembres en sus procesos y productos: Un análisis de su competitividad. Revista Facultad de Ciencias Económicas, 26(1), 113-124. https://doi.org/10.18359/rfce.2357

Mayta, R., & Mayta, J. (2017). Remoción de cromo y demanda química de oxígeno de aguas residuales de curtiembre por electrocoagulación. Revista de la Sociedad Química del Perú, 83(3), 331-340. https://doi.org/10.37761/rsqp.v83i3.117

Minag. (2022). Boletín oficial. Balance de los indicadores productivos. Ministerio de la Agricultura. Delegación territorial, Isla de la Juventud.

Nagi, M., He, M., Li, D., Gebreluel, T., Cheng, B., & Wang, C. (2020). Utilization of tannery wastewater for biofuel production: New insights on microalgae growth and biomass production. Scientific Reports, 10(1), 1530. https://doi.org/10.1038/s41598-019-57120-4

Natarajan, R., & Manivasagan, R. (2018). Treatment of tannery effluent by passive uptake-parametric studies and kinetic modeling. Environmental Science and Pollution Research, 25(6), 5071-5075. https://doi.org/10.1007/s11356-017-9456-9

Puente Guijarro, C. A. (2019). Curtición de pieles bovinas con Caelsalpinia spinosa en combinación con oxazolidina. Industrial Data, 22(1), 7-22. https://doi.org/10.15381/idata.v22i1.16522

Shi, J., Zhang, R., Mi, Z., Lyu, S., & Ma, J. (2021). Engineering a sustainable chrome-free leather processing based on novel lightfast wet-white tanning system towards eco-leather manufacture. Journal of Cleaner Production, 282, 124504. https://doi.org/10.1016/j.jclepro.2020.124504

Silva, V. (2021). Overview of the Leather Industry and Pollution Impact. U.Porto Journal of Engineering, 7(4), 1-15. https://doi.org/10.24840/2183-6493_007.004_0001

Vargas Doria Medina, D., & Amurrio Derpic, D. (2017). Alternativa de proceso de curtido con alto agotamiento de Cromo para las curtiembres tradicionales de la ciudad de Cochabamba. Acta Nova, 8(1), 3-30. http://www.scielo.org.bo/scielo.php?script=sci_abstract&pid=S1683-07892017000100002&lng=es&nrm=iso&tlng=es

Conflict of interest

Authors declare that they have no conflicts of interest.

Authors' contribution

All the authors reviewed the writing of the manuscript and approve the version finally submitted.